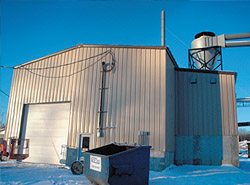

Completed in early 2007, Katahdin’s Biomass Boiler is one of the largest “green” improvements we’ve made to our manufacturing process – an investment of $980,000 constructed over 18 months. Prior to going on-line with the boiler, Katahdin was heating with fuel oil and having to truck away thousands of tons of waste sawdust and scrap each year. We had a constant battle to keep the sawdust from blowing into wastewater drains, into machinery and on our workers.

Completed in early 2007, Katahdin’s Biomass Boiler is one of the largest “green” improvements we’ve made to our manufacturing process – an investment of $980,000 constructed over 18 months. Prior to going on-line with the boiler, Katahdin was heating with fuel oil and having to truck away thousands of tons of waste sawdust and scrap each year. We had a constant battle to keep the sawdust from blowing into wastewater drains, into machinery and on our workers.

Recycle and reduce.

Now our 14 million BTU boiler cuts costs two ways: it has replaced 90 % of our fuel oil consumption and completely recycles our waste wood into steam heat. The state-of-the-art computer controlled 4,000-gallon boiler burns wood shavings produced during our manufacturing process to steam heat most of the buildings on the mill site. Since the biomass boiler has come on line, we’ve recycled more than 5,500 tons of sawdust each year.

How much heat?

The industrial-sized boiler could heat approximately 140 average homes. We’ve designed the biomass boiler with 50 percent more capacity than our current needs to allow us to expand.

How does it work?

The sawdust is collected from various locations on the mill site and moved to the boiler complex through a series of feeder tubes. The tubes lift the sawdust to a large hopper on the roof of the biomass building. The hopper then feeds a constant amount of sawdust into the firebox of the boiler to maintain a consistent heat and create steam. The steam is distributed among the mill buildings through a network of pipes. Computer sensors all along the production chain ensure that all parts of the biomass boiler system operate efficiently.

Meeting Clean Air Standards.

Oxygen sensors in the firebox maintain efficient combustion. A Multicyclone particulate collector captures coarser particulate matter before the smoke enters the 76-foot high stack. These devices result in minimal smoke, well below the maximum rates set by Maine law. Katahdin keeps close daily records of fuel combustion to meet both federal and state air quality regulations.

Multiple applications.

Little did we realize just how useful our biomass boiler would become. We can now utilize the steam from the boiler to “defrost” icy logs in the winter and use it to heat our finishing kiln. The boiler will also provide energy to run our ethanol distiller which (once it’s fully functional) converts local waste potatoes into fuel for our vehicles. It seems like every week we discover a new, inexpensive use for the steam!