Northern White Cedar is at the heart of everything at Katahdin Cedar Log Homes. We know cedar: scientifically proven to have superior resistance to aging, insects, rot, cracking, shrinkage, heat and cold when compared to pine. We know where to find it in sustainable forests, how to use every bit of the tree and save the very finest for our beautiful log homes. We make more cedar log homes than anyone in the US, and the most cedar fence anywhere. That makes Katahdin the largest primary processor of Northern White Cedar in the world. So what does that mean to you? CEDAR FOR THE PRICE OF PINE.

So, how do we do it?

Location

Simply put, the proximity of any manufacturer to its chosen natural resource will have a direct and measurable impact on the cost of the final product. This is true in every industry. It is far more expensive to ship raw materials than finished products. As one of the world’s most resilient tree species, Northern White Cedar grows in many areas across North America; however, there are only a couple places where the trees grow large enough and can be sustainably harvested. Our headquarters and manufacturing facility in Northern Maine is located in the middle of one of the largest cedar forests in the world. This means that we can buy cedar just as easily as we can buy pine. We don’t have to special order it like other log home companies that predominantly use other species.

Unparalleled Manufacturing

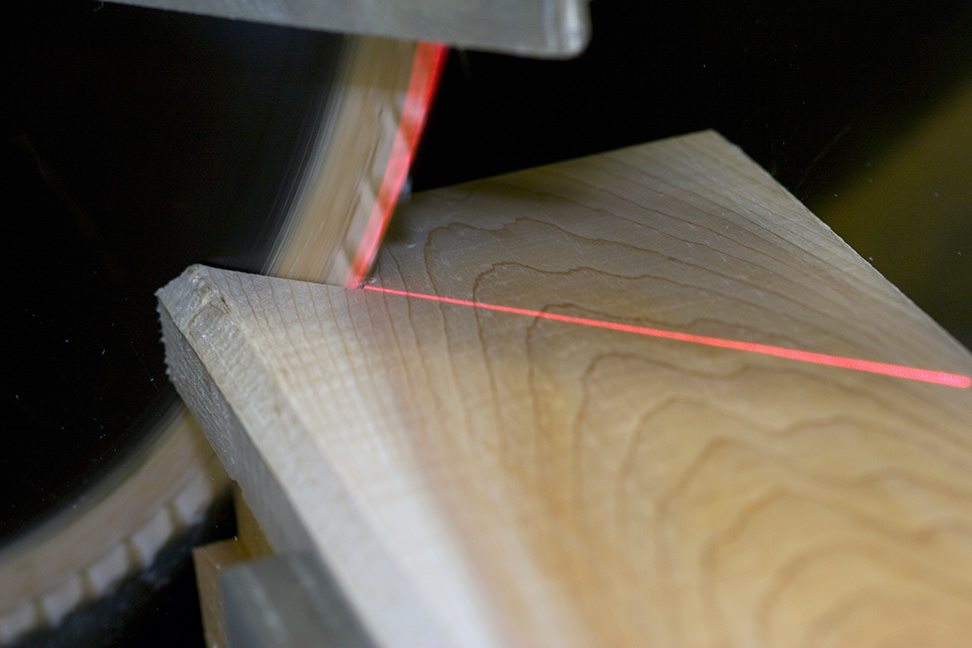

Our proprietary computerized log manufacturing line (the “House Line”) is the most efficient, precise and complete log home milling facility in the world. Each log that is run through the computerized system is: cut to length; labeled and barcoded; notched for corners; spliced for connections; pre-drilled for lag screws; ‘hand-peeled’ (optional); and sequentially stacked for optimized building. The House Line is operated by 2 people and can produce 2 averaged sized homes in 1 day. Homes are produced faster with less labor, greater precision, less waste and significantly more pre-cutting. What that means to you is greater quality at a more competitive price and significant time/money savings on the job site.

Our logs are our own

Our logs are our own

Unlike other log home companies, we are not purchasing pre-sawn timbers from another sawmill and paying their profits. We start with the whole tree purchased directly from local landowners and saw everything ourselves.

ZERO waste

Depending on the size and grade, any given log has the potential to produce nearly 200 different components for our three business segments – log homes, cedar fence and small garden products. Wood chips and bark are hauled away to make mulch, and all sawdust, shavings and scraps are fed into our biomass boiler that heats our entire manufacturing facility. Our ability to use every piece of every tree keeps our costs down which, in turn, keeps our prices down.

More control + more products = better quality

It’s simple – from the very beginning, if a timber doesn’t meet our exacting specifications for a log home it can easily be turned into another product that we sell. Companies that only sell log homes do not have this luxury and face greater pressure to use every timber in the home. This either results in lower quality or more waste and higher prices.