We love log raisings! They’re a great way to see just what happens when building a log home—it’s different from a typical framed building! Since we’re planning a bunch of Katahdin log raising events and open houses in the coming months, here are some log raising tips to look for when you attend a log raising.

The first thing to note is that log raisings can be in various stages of construction, from foundation to enclosing the exterior shell. You may or may not be able to see all the elements below, depending on where the builder is in the construction process.

- Check out the logs and insulation So many log home companies have different building systems. Check to see if the construction is whole logs or a combination of other materials, often called “hybrid construction.” Katahdin’s log homes are constructed using whole northern white cedar logs for the beneficial structural integrity, insulation value and long-lasting good looks. Northern white cedar is our log of choice because of its low moisture, stability and sustainable harvest. With less moisture, the logs can be enhanced on the inside of the log walls with insulation using our Energy Envelope System. This system allows homeowners to add energy- and money-saving insulation to keep cozy and comfortable all year long. Our insulation package also saves time and money because wiring can be installed directly, without having to drill the logs for outlets and wiring. Change your mind about a convenience outlet? These can be easily moved in a Katahdin log home.

- Look for “specialty logs.” Specialty logs are those that need additional cuts because of strategic locations in the home’s construction.

Katahdin’s computerized manufacturing line eliminates the guesswork and takes on-site cutting and drilling out of the equation. Here are some specialty logs to look out for, depending on the stage of construction:

Katahdin’s computerized manufacturing line eliminates the guesswork and takes on-site cutting and drilling out of the equation. Here are some specialty logs to look out for, depending on the stage of construction:

“A” Row This is the first row or course of the exterior log walls, which connects directly to the bottom plate and foundation. Katahdin’s A Row logs receive a specialty kerf cut at the mill— the XX slot— that allows for the insertion of flashing and log siding if desired for a tight seal at this critical intersection of foundation and wall.

“K” Logs These logs are positioned above windows and doors and are specially cut at Katahdin’s mill with kerfs for flashing, waterproofing, and sealing.

Gable logs Katahdin also includes trim or gable logs cut to match the roof pitch angle— precision construction that’s a real timesaver over other companies that leave this cutting to onsite workers.

Top Plate Row These logs are the final row or course of logs in the wall structure. They also receive a precision cut at the Katahdin mill to match the roof pitch. Structurally, this expands a single point of contact to the width of the log. This wider platform creates an area that is waterproofed, insulated and provides improved stability when positioning trusses and roof assemblies.

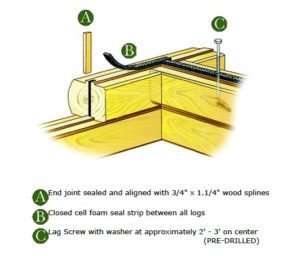

3. How straight are the walls? Over our 40-plus years of experience, we’ve improved our construction design. One of these design changes  helps to keep walls straight and creates a more structurally sound home. Each cedar log we prepare for wall stock receives a wide tongue and groove cut that locks the logs together tightly over the length of the log. This expanded area allows the sealing for each log seam to be tight, waterproofed and sound.

helps to keep walls straight and creates a more structurally sound home. Each cedar log we prepare for wall stock receives a wide tongue and groove cut that locks the logs together tightly over the length of the log. This expanded area allows the sealing for each log seam to be tight, waterproofed and sound.

4. Take a look at the log packs on the construction site. Many companies package logs without a plan, forcing the builders to unpack, sort and organize all the logs before starting. If there are Katahdin log packs on site, you’ll note that each log pack has a ticket that inventories the contents of each packet. Further, each pack is sorted so that logs can be unpacked in relative construction order. This helps keep the remainder of the log packs sealed and safe from the elements. If you  look closely, you’ll notice that each log is pre- numbered, pre-cut and pre-drilled to correspond to the plans. Also included in the log package — and a familiar sight at our log raisings— rolls of foam strip, splines and caulk for proper and meticulous sealing for each course of the log walls.

look closely, you’ll notice that each log is pre- numbered, pre-cut and pre-drilled to correspond to the plans. Also included in the log package — and a familiar sight at our log raisings— rolls of foam strip, splines and caulk for proper and meticulous sealing for each course of the log walls.

5. Ask about window and door bucks. Windows and doors are often the source of the most air infiltration in homes. In log homes, window and door bucks are made to seal the gap between the log ends and the window frame. Bucks are specially cut wood strips that provide double sealing for these openings. Unlike some other companies, Katahdin provides all window and door bucks pre-cut to ensure the tightest seal. The bucks are splined to the log wall opening, flashing and caulking applied and then sealed in a second layer with trim around the windows and doors.

We are proud of our precision manufacturing and construction techniques! Our upcoming log raisings and open houses offer you the chance to understand how our homes are built for long-lasting and comfortable living. Check out upcoming log raising events here. If you’re in New England, it’s certainly worth the drive to attend our Western Maine Logapalooza event on Saturday, June 17. This special event will feature nine homes to tour, with some still under construction.