No, it’s not your imagination— log homes are warmer than traditional “stick-built” homes and there’s some science behind this concept.

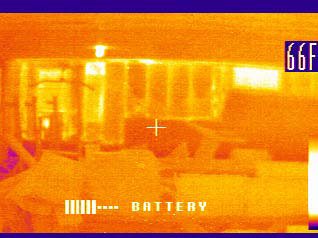

Insulation is a substance that slows or limits the transfer of heat over time. In wood frame or “stick-built” homes, the insulation (generally in the form of fiberglass batting) is installed between the vertical studs that form the framework of the wall. These fiberglass bats or other insulation materials are good at keeping the heat in. However, what many people don’t understand is that the studs that connect exterior and interior surfaces actually conduct heat out of the interior of the home. The wood studs are not as insulating as the fiberglass bats. This effect is called thermal bridging and can be most easily understood by looking at the heat loss in a wall through infrared imaging. The image at left shows how studs can conduct heat out of the interior of a basement.

Insulation is a substance that slows or limits the transfer of heat over time. In wood frame or “stick-built” homes, the insulation (generally in the form of fiberglass batting) is installed between the vertical studs that form the framework of the wall. These fiberglass bats or other insulation materials are good at keeping the heat in. However, what many people don’t understand is that the studs that connect exterior and interior surfaces actually conduct heat out of the interior of the home. The wood studs are not as insulating as the fiberglass bats. This effect is called thermal bridging and can be most easily understood by looking at the heat loss in a wall through infrared imaging. The image at left shows how studs can conduct heat out of the interior of a basement.

Log homes, on the other hand, are constructed of logs that provide a continuous insulation barrier, with few irregularities in width or densities. Katahdin has used Northern White Cedar for its log homes for its superior insulating properties, the highest of all softwoods commonly used for log homes.

According to the Department of Energy website, in mild, temperate areas, logs can even act as “thermal batteries” storing warmth during the day and slowly releasing it at night, which increases the apparent insulation rating of the log walls. These areas are generally those south of the 40th parallel in the US, or roughly the lower boundary of Pennsylvania and the border between Nebraska and Kansas.

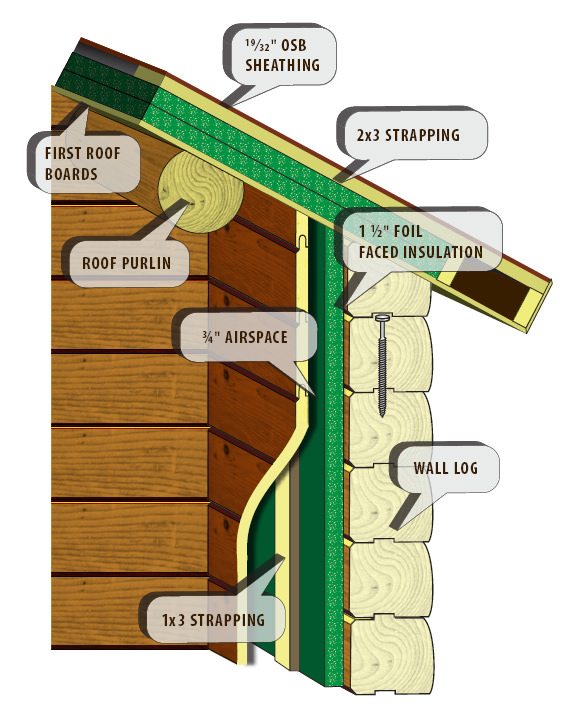

Katahdin further enhances this continuous insulation barrier with their Energy Envelope System. This unique system uses Thermax™, an advanced, foil-faced rigid sheet insulation, and a 3/4-inch airspace to inhibit thermal loss in exterior walls. The system is finished on the interior with shaped paneling that maintains the log wall effect on the interior of the home. This increases the performance of the cedar log walls, and enhances the energy efficiency of the home dramatically. Katahdin uses a similar approach with its roof systems.

Katahdin further enhances this continuous insulation barrier with their Energy Envelope System. This unique system uses Thermax™, an advanced, foil-faced rigid sheet insulation, and a 3/4-inch airspace to inhibit thermal loss in exterior walls. The system is finished on the interior with shaped paneling that maintains the log wall effect on the interior of the home. This increases the performance of the cedar log walls, and enhances the energy efficiency of the home dramatically. Katahdin uses a similar approach with its roof systems.

And this performance becomes evident, when Katahdin homes are tested upon completion. The standard test of “tightness” or minimal thermal leakage is the blower-door test. In the test, the entrance to the home is fitted and sealed with a specially designed, powerful fan. This blower door fan evacuates air from the interior of the home, lowering the air pressure in the home. The tester can also monitor areas of the home with infrared cameras, to determine where any infiltration might occur. Generally, areas of concern are around windows and doors, where walls and ceilings join, electrical fixtures (right), and in heating and cooling ductwork.

Performance is also key in light of new energy efficiency codes all states will be adopting beginning early next year. The 2009 International Energy Efficiency Codes (2009 IECC) are tied to the American Recovery and Reinvestment Act of 2009. States that have received funds from this stimulus package are compelled to revise and update their building codes to meet these new requirements. Some log home companies are hoping for exemptions to the codes for log homes, but at Katahdin, we wonder why anyone would want a product that is less energy efficient than it could be.