Wood pellets have been around for decades, but the conversion into a viable heating solution in the U.S has been slow to catch on. European fully-automatic pellet central heating systems have been up and running successfully for over a decade. Not until recently have systems designed to burn wood pellets as a primary fuel source in homes been available on a widespread basis, allowing Americans to enjoy the convenience and money savings of a modern pellet system.

Wood pellets have been around for decades, but the conversion into a viable heating solution in the U.S has been slow to catch on. European fully-automatic pellet central heating systems have been up and running successfully for over a decade. Not until recently have systems designed to burn wood pellets as a primary fuel source in homes been available on a widespread basis, allowing Americans to enjoy the convenience and money savings of a modern pellet system.

Because Katahdin’s homes are made from sustainable Northern White Cedar, we have a certain affinity for sustainable ways to heat our log homes. We use a biomass boiler to recycle the wood sawdust we create at the mill complex. Other residential solutions for using the abundant wood resources available to us here in Maine have been limited to wood stoves, wood boilers and other stove-like solutions.

Wood pellets have always been appealing, because of their clean burning qualities and low cost. However, many homeowners were put off by the necessity to use wood pellets in specialized pellet stoves. Like traditional wood stoves, the pellet stoves required a lot of attention and physical labor to stock the pellets and regulate heat output. Pellets came in bulky 40-pound sacks, and a dry storage area was required for the palletized sacks of pellets. The sacks were susceptible to mold and dampness.

Simplifying Wood Pellet Heat

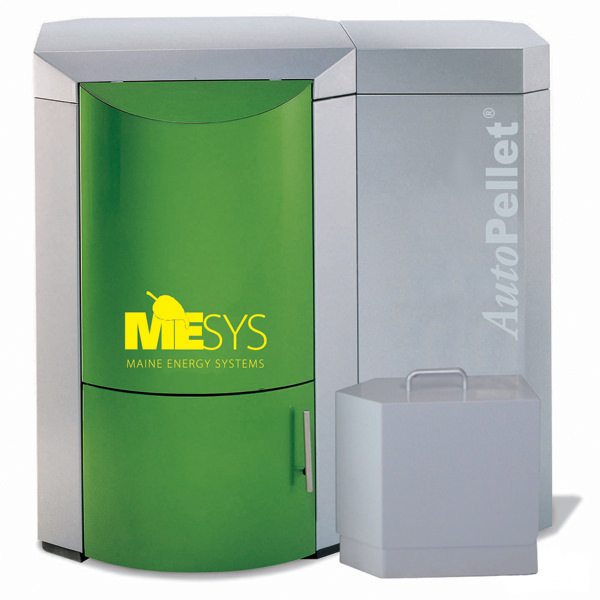

Making wood pellet heat as simple a system as oil heat, has long been a goal of sustainable energy enthusiasts in the U.S. One company has taken on the wood pellet heat solution and created a system that works in just about any residential setting. Maine Energy Systems, or MESys, has taken on both the heat production and the delivery  component of wood pellets. We spoke with President and CEO Les Otten, about his company and how he hopes to evolve heating in the U.S. away from foreign fossil fuels and toward fuels the country has in abundance. And the savings from wood pellet heat are substantial!

component of wood pellets. We spoke with President and CEO Les Otten, about his company and how he hopes to evolve heating in the U.S. away from foreign fossil fuels and toward fuels the country has in abundance. And the savings from wood pellet heat are substantial!

“Consumers have been limited by a lack of information and investment in making wood pellet systems work in the U.S.,” said Otten, who is passionate about his company’s approach to fuel. “In Europe, biomass fuels and pellet systems have been as simple to operate as adjusting the thermostat,” he said. “Now we have the capability to make wood pellet systems a viable investment for the U.S. homeowner.” Once consumers understand how simple and how inexpensive these systems are to operate, Otten believes they will catch on—especially in the colder climates.

Automatic Pellet Boilers

Developing a reliable boiler system that efficiently burned the pellets and heated water both for the central heating system and domestic hot water was the first step. Otten’s company manufactures several models suited for new construction or to retrofit into an existing homes hot water heating system. His design answers many homeowners’ concerns and misperceptions about using pellets for heat.

The boiler is rated at 87.7% efficiency and features a two-stage combustion chamber. The boiler sports a programmable LCD controller to control output. The units are equipped with safety features that prevent burnback fires and sensors that continuously monitor burner efficiency. Ash removal is clean and simple, requiring no boiler downtime to accomplish and is only necessary 3-4 times per year in a typical home. The ash is automatically collected in an external detachable ash box about the size of a large briefcase. Pellets automatically fuel the boiler through a vacuum or auger feed system. The fine ash the boiler produces provides an inexpensive source of organic fertilizer for lawns or gardens.

Pellet Delivery and Storage

Fuel storage is a unique system on its own: MESys fully-automatic pellet boiler systems feature a fabric storage bin that occupies a 7-foot x 7-foot area near the boiler; smaller bins are also available. The space used by the bin is equivalent to two standard fuel oil tanks. The fabric is constructed using carbon fiber and advanced weaving to allow air to circulate around the pellets without allowing any dust or pellets to escape. It works much like the collector bag in a vacuum cleaner does, just on a larger scale. The large bin stores five tons of pellets, enough for six months of heating.

The permeability of the storage bin plays a role in the pellet delivery process. The pellets are delivered to the home via specially designed trucks that are attached to the storage bin system through a 4-inch hose, similar to the fuel oil delivery set up. The difference is in the trucks, which have powerful pneumatic pumps in the cargo tanks. These air pumps ”fluidize” the pellets so that they can be pumped with air pressure (about 4 pounds per square inch or psi) into the storage bin in the home. The pneumatic trucks are equipped to deliver 4-5 tons of pellets in about 20 minutes.

The permeability of the storage bin plays a role in the pellet delivery process. The pellets are delivered to the home via specially designed trucks that are attached to the storage bin system through a 4-inch hose, similar to the fuel oil delivery set up. The difference is in the trucks, which have powerful pneumatic pumps in the cargo tanks. These air pumps ”fluidize” the pellets so that they can be pumped with air pressure (about 4 pounds per square inch or psi) into the storage bin in the home. The pneumatic trucks are equipped to deliver 4-5 tons of pellets in about 20 minutes.

Official Recognition

One of the biggest barriers to adoption of a new heating technology, according to Otten, is its ability to be financed and insured. Once the US Dept of Housing and Urban Development (HUD) recognized automatic pellet boiler systems as “commonplace and ordinary” they were able to be included in mortgages, and covered by homeowners insurance. “We have a list of mortgage lenders and insurance companies who recognize and insure MESys pellet systems,” Otten said. Financing for retrofit systems is also available through a third-party lender that MESys has established a relationship with.

Maine Energy Systems has recently been awarded the Governor’s Award for Environmental Excellence in Maine for their clean energy efforts.

Short-term payback, long-term savings

Most heating systems for a 2,500 square foot home can cost about $10,000. A comparable MESys boiler costs around $18,000 installed, but the difference in initial investment is quickly recouped in fuel cost savings. Otten estimates that the average well insulated home can save about $2,000 per year in fuel costs, assuming the price of fuel oil stays the same. The MESys website has a calculator tool to assist homeowners in determining their estimated savings. Otten’s company sells the pellets in bulk to homeowners at the cost equivalent of $1.99/gallon of heating oil, almost half the price of fuel oil.

Wood Pellet Availability

With any new source of fuel, it’s essential to determine the availability and pricing of the fuel itself. Wood pellets have been in production for decades now, and some producers have seen the demand for their product increase tenfold as new systems come online for delivery and consumption. Matt Bell, owner of Northeast Pellets in Ashland, Maine, purchases dry wood materials from mills in Maine and New Brunswick, Canada, to make his pellets. He saves processing and expense by purchasing the wood that is already dried and contains no bark, usually from planer mills. “The result is a better pellet that produces less ash,” Bell said. Right now his market is in bulk production, ranging from Eastern Canada to southern New England. Some producers in New England are beginning to research export to Europe, where pellet markets are well established, but where wood products are limited.

Bell said that many larger commercial facilities are switching over to pellet systems for heat, including three Aroostook County colleges. These schools are among those who have benefited from a Maine Forest Service Wood-to-Energy Public Building Grant program for biomass fuel systems. MESys provided wood pellet boiler systems for the Waterville (Me.) High School and Gardiner (Me.) City Hall under the grant program.

Bell said that many larger commercial facilities are switching over to pellet systems for heat, including three Aroostook County colleges. These schools are among those who have benefited from a Maine Forest Service Wood-to-Energy Public Building Grant program for biomass fuel systems. MESys provided wood pellet boiler systems for the Waterville (Me.) High School and Gardiner (Me.) City Hall under the grant program.

Other benefits

One of the reasons Otten saw pellet systems as a viable industry is the way in which it keeps investments in the U.S. The MESys boilers are manufactured in Maine, the trees that are harvested are an abundant, renewable and sustainable resource in the U.S. The pellet system frees consumers from the economic hold that foreign sources of fuel have. “We now have the capability to move toward a more self-sufficient method of keeping warm,” Otten said. “We just need to educate people that it really is as easy as turning the thermostat.”