In the first of a two-part series about conventional fuels we’ll explore options for heating your log home. Today there are many options for keeping your home comfortable in winter months. Selecting the right one for your needs can be challenging considering the choices available. Many home owners design heating systems with primary and secondary options, such as wood stove heating backed up with propane fired baseboard hot water. This part of the series will explore different wood-based fuel options: cut wood, pellets and bricks.

In the first of a two-part series about conventional fuels we’ll explore options for heating your log home. Today there are many options for keeping your home comfortable in winter months. Selecting the right one for your needs can be challenging considering the choices available. Many home owners design heating systems with primary and secondary options, such as wood stove heating backed up with propane fired baseboard hot water. This part of the series will explore different wood-based fuel options: cut wood, pellets and bricks.

Cut Wood. For areas with abundant and nearby forested areas, cut wood may be the most basic and least expensive form of heating a home. Once you get the hang of it, heating with a wood-fired stove or wood furnace provides a lot of BTUs for the dollar. There are some factors to consider:

- Storage. If you’re planning ahead you’ll be ordering your green wood now for 2013. It’s the least expensive way to fuel a wood stove, but

you’ll need to stack and cover the wood supply for seasoning to provide a clean dry burn. Storing enough wood for several heating seasons can take up a fair amount of space. You may be able to locate downed hardwood on your property that can be split for use in the woodstove, but you’ll probably need to supplement with professional cut sticks. An old Maine saying reminds us: “Wood heats three times. Once to cut it, once to stack it, and once to burn it.” Wood can require some energy.

you’ll need to stack and cover the wood supply for seasoning to provide a clean dry burn. Storing enough wood for several heating seasons can take up a fair amount of space. You may be able to locate downed hardwood on your property that can be split for use in the woodstove, but you’ll probably need to supplement with professional cut sticks. An old Maine saying reminds us: “Wood heats three times. Once to cut it, once to stack it, and once to burn it.” Wood can require some energy. - Woodstoves. The stove you select can put out some good heat, and some elements can enhance the duration of the fire. If your woodstove has brick or stone walls or surrounds, these will capture heat and stay warm for hours after the stove has gone out. Soapstone stoves seem to have more heat retention than cast iron, but sometimes its more a matter of style and design as to the right stove for your situation. One extremely important benefit for the basic woodstove is that when your power goes out, you can still heat your home, and even cook if necessary.

- Maintenance. Even with the assumption of clean burning hardwoods, there is an art to starting and maintaining a fire over the course of a day. Make sure your stovepipe has an active damper to control the rate of burn. This will keep your chimney cleaner of creosote buildup and keep BTUs from flying up the chimney instead of into your home. An annual check-up and professional cleaning for the chimney, flashing, and stove is necessary, if you are heating with wood rather than an occasional fireplace fire for atmosphere.

- Boilers. Wood fired boilers are another option for heating with wood, but they are subject to more EPA regulation and may cause problems with nearby neighbors if the smoke is too heavy.

Pellet Stoves. These have become popular with homeowners who wanted the relatively inexpensive fuel of wood products, without the bigger challenges of cut wood. Early issues with pellet stoves have been overcome with electronic controls, push-button ignition, and quieter blower fan assemblies. Pellet stoves come in many different configurations and sizes, so you’ll need a good idea of the size of the area you need to heat with one. The heating area will determine other features such as hopper size, blower power, electronic thermostat, and other features. The factors to consider when researching pellet stoves include:

Pellet Stoves. These have become popular with homeowners who wanted the relatively inexpensive fuel of wood products, without the bigger challenges of cut wood. Early issues with pellet stoves have been overcome with electronic controls, push-button ignition, and quieter blower fan assemblies. Pellet stoves come in many different configurations and sizes, so you’ll need a good idea of the size of the area you need to heat with one. The heating area will determine other features such as hopper size, blower power, electronic thermostat, and other features. The factors to consider when researching pellet stoves include:

- Pellets. Pellets are manufactured products made from waste sawdust and other biomass materials. Higher quality pellets are formed under extremely high pressure, while lower quality pellets will use resins to hold the materials together in a pellet shape. The e-how website has some good tips for shopping for pellets here. One potential problem with pellets is that they are manufactured as a byproduct of other wood-based industries. If a paper or lumber mill is not producing as much, less waste sawdust is produced and fewer pellets will be produced creating supply issues.

Some lesser quality pellets produce more ash and lower BTUs than more expensive pellets, but prices can vary widely so it pays to shop around.

Some lesser quality pellets produce more ash and lower BTUs than more expensive pellets, but prices can vary widely so it pays to shop around. - Storage. Pellets are sold in 40-pound bags, generally stacked on pallets for easy distribution. You’ll need to set aside a dry storage area for your pallet of wood pellets, because if they become exposed to excess moisture, they will become unusable. Some people find the pellet bags are easier to handle than cut wood, and thus opt for this more “value-added” approach.

- Electricity costs. Pellet stoves require electricity to operate, with their electronic thermostats, blower fans and air flow monitors. Some estimates predict as much as 100kWh per month, though other stoves may require only about $10 per month to operate.

- Maintenance. With more moving parts, pellet stoves can be labor intensive. Ash pans need to be emptied regularly, vents and exhausts cleaned. Lower quality pellets can produce more ash, so pellet selection can affect maintenance tasks. The glass doors may require more cleaning if your unit doesn’t include an airflow monitor to keep the flame away from the glass.

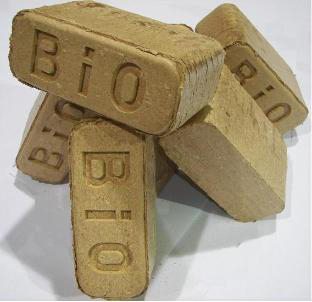

Bricks. These are another sawdust-based product but instead of pellets the sawdust is form into stackable brick shapes. These are easier to store and come packaged on pallets for easy transport. Unlike pellets, they can be burned in a conventional wood stove. Many people use these as supplemental fuel to stretch a limited supply of cut wood. Like pellets, sawdust-producing industries can adversely affect production, availability and cost. Marketed under several names, including BioBricks and BTU Bricks, they burn more cleanly than cut wood and thus will produce less ash. Most manufacturers claim a one-to-one comparable BTU production between a pallet of bricks and a cord of hardwood.

Bricks. These are another sawdust-based product but instead of pellets the sawdust is form into stackable brick shapes. These are easier to store and come packaged on pallets for easy transport. Unlike pellets, they can be burned in a conventional wood stove. Many people use these as supplemental fuel to stretch a limited supply of cut wood. Like pellets, sawdust-producing industries can adversely affect production, availability and cost. Marketed under several names, including BioBricks and BTU Bricks, they burn more cleanly than cut wood and thus will produce less ash. Most manufacturers claim a one-to-one comparable BTU production between a pallet of bricks and a cord of hardwood.

Tune in next month when we compare fuel oil, propane and natural gas options for heating.